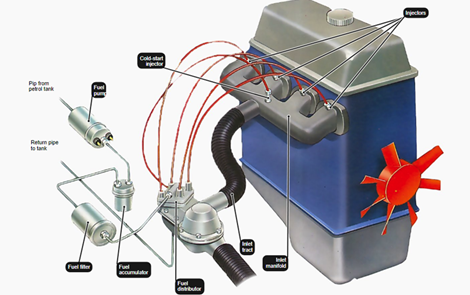

Fuel pump Assembly is the source of power for diesel engines. It is the most important component of diesel engine fuel supply system. Its role is to provide diesel fuel for

injectors regularly and quantitatively. It is the key to correcting the normal operation of diesel engines. Understanding the failure of the

fuel injection pump and correct it properly is a very important part of the maintenance work. Below by the

fuel pump Assembly and parts system expert - Guangzhou Rui xiao Trade Co., Ltd. to explain the relevant knowledge to you, teach you how to determine the failure, troubleshooting.

A. Diesel engine can not start

The reason why the diesel engine cannot start is that the low pressure oil line cannot supply oil to the injection pump

1.There is air in the oil circuit. The treatment method is to loosen the oil pump deflation screw, use the hand oil pump to send oil to the

fuel pump, remove the air, and tighten the bleeder screw. If this does not work, you can loosen the air filter. Drain the tubing connector and exhaust it with a bleeder screw.

2.The low-pressure oil line blockage makes the low-pressure oil cavity oil-free. The main reason is that the oil pump filter and the filter are dirty and can be removed

3.The oil pump failed to supply oil to the

fuel injection pump. The oil pump component failed and the cause was identified and replaced.

4.The oil pipeline or connection to the high pressure oil pump is seriously leaking. Check if the tubing connector is loose or the tubing is damaged.

B.Diesel engine is weak

The main reason for the inability of diesel engines is the lack of oil from the injection pump

1. The fuel supply to the fuel injection pump is insufficient because the fuel pump is faulty. Replace it.

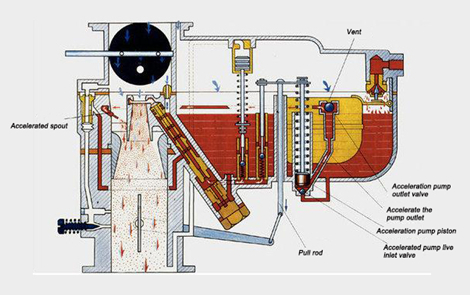

2. Insufficient supply of fuel to the

injector by the injection pump. The reason is that the

plunger, oil valve, spring and other oil pump parts are worn out, and replacement of new parts will do.

C. Diesel engine oil vehicle

The reason for diesel engine oil tank failure is that the fuel supply from the injection pump to each cylinder is not uniform or the governor is not working properly.

1. Uneven oil supply to each cylinder should adjust the oil supply non-uniformity at the injection pump test bench.

2. The pressure difference between the cylinders is too large and the quality of the atomization is different, which makes the engine speed unstable.

3. The flyweights of the governor are inflexible and the rotation is not stable due to poor coupling.

4. The governor drive and connection wear

5.If the idle speed is not proper, the lower the speed, the greater the unevenness of the oil supply, and the idle speed can be increased by adjusting the limit screw.

D. Diesel engine speed is not up to standard

The reason why the speed of the diesel engine does not meet the standard is that the fuel injection pump control lever is not pulled, and the maximum fuel supply is low.

1. The control handle does not reach the position and cannot be in contact with the maximum oil limit screw. Please check the exit length of the secondary throttle limit screw and whether the pedal stroke is too small.

2. The governor governor spring becomes softer, longer, and less tensioning.

3. Fuel injection pump control gear rod jam

E. Diesel Speed

The diesel engine coaster is caused by the out-of-control of the fuel speed controller of the fuel injection pump and its governor. The reason is that the fuel injection pump adjusts the rod to be stuck or the connecting pin falls off, and the governor spring breaks. It must be disposed in time, otherwise the consequences are serious.

There are three ways to take emergency measures on the coaster. They are cut off oil, cut off gas, and turn off the flames.

1. Shut off the oil, control the throttle to the parking position, that is, cut off the oil, immediately release the injection pump inlet pipe, cut off the oil circuit.

2. Air shut off: block the intake of the diesel engine, cut off the gas path, and force the engine to stop

3. Shut down the flame: quickly put on the high-end, the use of internal braking or external braking forced flameout.

The decompression device of the diesel engine shall also immediately pull the handle of the decompression device. After stopping the speeding car, check and immediately eliminate the malfunction.

The working status of the fuel injection pump and the governor directly and seriously affects the work of the diesel engine. Attention must be paid to it, and the maintenance and repair should be strengthened. The inspection, adjustment and maintenance of the fuel injection pump and the governor are all performed on the test bench.