Customer Hot Line:

+86 15622179651Your current position:home > Diesel injection news

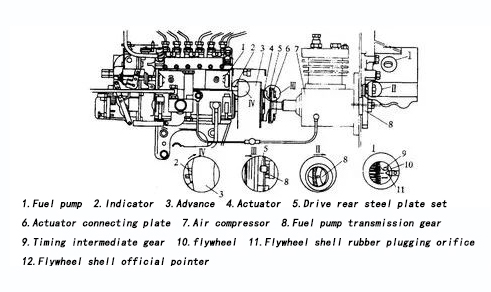

In order to check and adjust the fuel supply advance angle, when manufacturing the diesel engine, the manufacturer generally marks the timing at the corresponding position of the diesel engine and the Mechanical fuel pump:

It refers to the fixed time line on the Mechanical fuel pump coupling (or automatic advancer) and the oil pump bearing cover. So long as the two lining lines are aligned, it is sure to become The time when the Mechanical gas pump starts to supply oil to the first cylinder;

The individual identifies the engraved collection on the front end of the crankshaft. And a pointer on leading cover of the body;

For the multi-cylinder diesel engine, the unloading advance position of the oil supply can be confirmed. The meshing mark of the Mechanical energy pump and the corresponding tranny gear may be aligned after the diesel engine is usually overhauled, Individual models also pay attention to the connection mark when installing the Mechanical gasoline pump.

The timing of the oil supply could be inaccurate due to various conditions. In this instance, it is necessary to check the timing of the essential oil supply.

(a) When one person swings the crankshaft to make the I actually cylinder piston in compression stroke (ie, there is a gap between the I cylinder inlet and the exhaust valve), when the fixed mark is just aligned with the fuel advance angle mark on the flywheel or the crankshaft belt wheel, stop. Shake the crankshaft.

(b) For the 1st pump of the Mechanical gas pump to start the oil supply timing tag, check whether the fixed time line mark upon the coupling (or automated advancer) is opposing to the scribed indicate on the front end of the pump casing. If both marks are right, the energy supply timing is right; if the marking on the coupling has not yet reached the pump casing marking, the oil supply time is definitely too late;

For the coupling and leading end of the pump casing, there is no scribed mark. At this time, the high pressure essential oil pipe of the Mechanical gasoline pump I should be eliminated, and one individual should turn the crankshaft. When it is about to reach the position of the oil supply advance angle of the I cylinder, slowly crank the crankshaft. One person gaze at the essential oil level of the oil wall plug of the I-cylinder outlet valve. When the oil level has just moved upward, quit cranking the crankshaft and examine if the fuel supply enhance position on the flywheel or crankshaft tape wheel can be opposite to its corresponding pointer ( For the convenience of future inspection, a couple of timing marks could be added to the coupling and the pump casing.

The fuel supply timing must be checked.

(a) Rotate the crankshaft clockwise so that the initial cylinder piston is at the fuel supply start position before the top dead center of the compression stroke, that is, the fixed mark is certainly aligned with the gas supply advance angle mark on the flywheel or the crankshaft belt wheel.

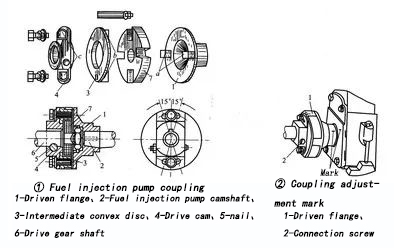

(b) Turn the energy pump camshaft to ensure that the fixed period line mark upon the gasoline pump coupling (or automatic advancer) is aligned with the score tag on the front end of the pump casing.

(c) Push the Mechanical fuel pump forward so that the lug of the driven flange disc is usually inserted into and engaged with the coupling. When tightening the two screws of the active flange disc and the intermediate flange disc, both flanges should be made. The "0" indicate on the disc is definitely aligned, to ensure that the gas supply advance angle of the diesel engine can be guaranteed.

If the fuel supply advance position is found to be too small or too large, adjustments should be made. Common adjustment methods are:

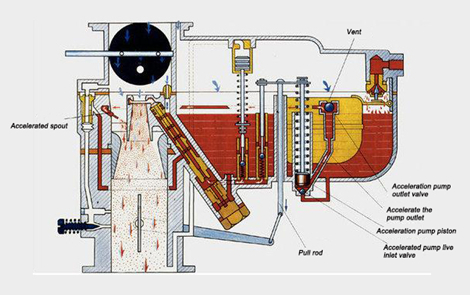

(1) Rotating pump body adjustment

There are 3 or 4 curved long holes on the triangular fixing plate and the flange. Use the above method to fix the Mechanical energy pump. If the oil supply timing is not correct, simply loosen the corresponding three or four 4 repairing bolts, and rotate the pump body through the curved lengthy hole to change the oil supply progress angle.

When adjusting, the pump body is rotated by an angle against the rotation direction of the generating wheel, so that the fuel supply advance angle could be increased; if the pump body can be rotated along the driving wheel, the gasoline supply advance angle can be reduced.

(2) Rotating pump shaft adjustment

When adjusting the essential oil supply advance angle, the two fixing bolts on the connecting plate could be loosened, and the fuel pump camshaft can be rotated by one position to boost the oil supply enhance angle; when the reverse rotation direction is certainly rotated by an angle, the oil could be reduced. Small oil supply progress angle. After adjustment, tighten the 2 2 repairing bolts on the linking plate.

Release time:2019-06-23 Text source:Guangzhou Ruixiao Trading Co.,

When the diesel generator set is in use, it may be automatically turned off ......

Release time:2019-06-10 Text source:Guangzhou Ruixiao Trading Co.,

For the engine to run smoothly and efficiently it needs to be......

Release time:2019-04-17 Text source:Guangzhou Ruixiao Trading Co.,

Why does the bus and truck emit black smoke? 1: The oil supply of .......

Release time:2019-04-12 Text source:Guangzhou Ruixiao Trading Co.,

Why are there fewer cleaner injectors now, are they not cleaned, and how ......

Release time:2019-03-31 Text source:Guangzhou Ruixiao Trading Co.,

The maintenance of the injector is a precise and technically demanding......